Product range:

high modulus (HM), high tenacity (HT), high modulus low shrinkage (HMLS) yarns

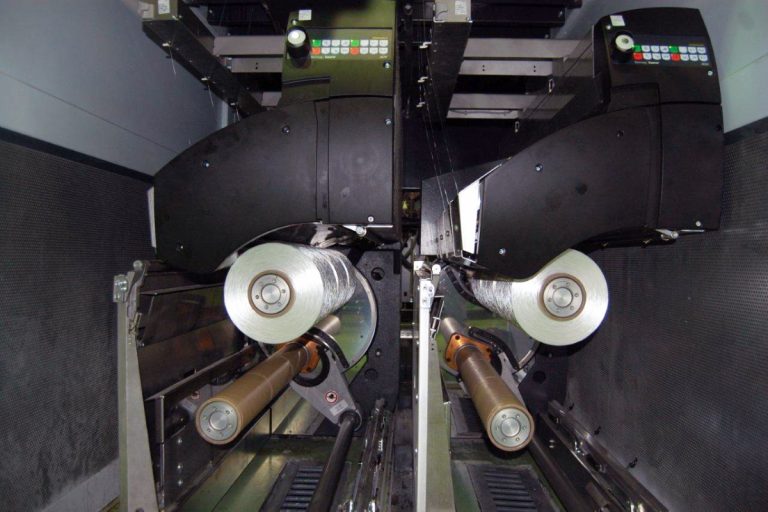

The production of polyester yarns is equipped with the most modern, high-tech equipment

of the world’s leading manufacturers in the field of mechanical engineering.

ADVANTAGES OF POLYESTER YARNS

- Resistant to light, climate and atmospheric conditions;

- Lightness and delicacy of the material;

- Low tendency to crush, moisture resistance;

- Good moisture transfer ability, dry quickly;

- Do not require special care;

- High strength, excellent wear resistance.

POLYESTER YARNS APPLICATION

With a variety of physical and chemical properties of polyester yarns their scope is extensive, which makes this product unique, modern and versatile for many industries.

The main application of polyester yarns are:

- Cord fabrics production;

- Technical fabrics production;

- Geotextile and geogrids production;

- Transmission belts production;

- Conveyor belts production;

- Textile slings and high load capacity tape production.

TECHNICAL CHARACTERISTICS OF POLYESTER EXTENDED YARNS TYPE HM

High modulus polyester yarns (HM) are intended for the production of technical fabrics, geotextiles, mechanical rubber goods and other products, for sewing bags with food and non-food bulk products, for the production of technical filter fabrics.

| HIGH MODULUS POLYESTER YARNS (HM) | |||||

| Indicator | 1100 dtex | 1440 dtex | 1670 dtex | 2200 dtex | 3300 dtex |

| Yarn type | HM | HM | HM | HM | HM |

| Nominal Linear Density, dtex | 1120 ± 50 | 1460 ± 50 | 1690 ± 50 | 2250 ± 50 | 3300 ± 100 |

| Breaking load, N | ≥ 88 | ≥ 114 | ≥ 133 | ≥ 178 | ≥ 260 |

| Specific breaking load, cN/dtex | ≥ 7,8 | ≥ 7,8 | ≥ 7,8 | ≥ 7,8 | ≥ 7,8 |

| Elongation at a load of 45N, % | 5,5 ± 0,5 | 4,5 ± 1 | 4,0 ± 1 | at 90 H 6,5 ± 0,7 | at 135 H 6,1 ± 0,7 |

| Elongation at break, % | 12,5 ± 1 | 12,5 ± 1 | 12,5 ± 1 | 12,5 ± 1 | 12,5 ± 1 |

| Linear shrinkage of the yarn at 177 ° C x 2 min x 0.05 cN/tex | 8,0 ± 2,0 | 8,0 ± 2,0 | 8,0 ± 2,0 | 8,0 ± 2,0 | 8,0 ± 2,0 |

| Mass fraction of spinning oil on the yarn | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 |

| Number of pneumatic connections per 1 m. | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 |

TECHNICAL CHARACTERISTICS OF POLYESTER EXTENDED YARNS TYPE HT

The main field of application of high tenacity polyester yarns (HT) is the production of technical fabrics, power tapes, geogrids. HT yarns are characterized by high tenacity strength – not less than 8,1 cN/dtex.

| HIGH TENACITY POLYESTER YARNS (HT) | ||||||

| Indicator | 1100 dtex | 1440 dtex | 1670 dtex | 2200 dtex | 3300 dtex | 4400 dtex |

| Yarn type | HT | HT | HT | HT | HT | HT |

| Nominal Linear Density, dtex | 1160 ± 50 | 1480 ± 30 | 1680 ± 50 | 2250 ± 50 | 3350 ± 70 | 4500 ± 120 |

| Breaking load, N | ≥ 94 | ≥ 120 | ≥ 136 | ≥ 178 | ≥ 267 | ≥ 340 |

| Specific breaking load, cN/dtex | ≥ 8,1 | ≥ 8,1 | ≥ 8,1 | ≥ 8,1 | ≥ 8,1 | ≥ 7,5 |

| Elongation at a load of 45N, % | 6 ± 1 | 5 ± 1 | 4,5 ± 1 | at 90 H 6,7 ± 0,7 | at 135 H 6,8 ± 0,7 | at 170 H 7,5 ± 1 |

| Elongation at break, % | 14 ± 1 | 14 ± 1 | 14 ± 1 | 14 ± 1 | 14 ± 1 | 15 ± 2 |

| Linear shrinkage of the yarn at 177 ° C x 2 min x 0.05 cN/tex | 5 ± 1 | 5 ± 1 | 5 ± 1 | 5 ± 1 | 5 ± 1 | 5 ± 1 |

| Mass fraction of spinning oil on the yarn | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 |

| Number of pneumatic connections per 1 m. | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 |

TECHNICAL CHARACTERISTICS OF POLYESTER EXTENDED YARNS TYPE HMLS

High modulus low shrinkage polyester yarns (HMLS) have lower elongation at break and lower shrinkage than HM yarns.

The main area of use is the production of cord fabric for the tire industry.

| HIGH MODULUS LOW SHRINKAGE POLYESTER YARNS (HMLS) | ||||||||||

| Indicator | 1100 dtex | 1440 dtex | 1670 dtex | 1870 dtex | 2200 dtex | |||||

| Yarn type | HMLS | НТ HMLS | НМLS | HT НМLS | НMLS | НТ НMLS | НМLS | НТ НMLS | НМLS | НТ НMLS |

| Nominal Linear Density, dtex | 1150 ± 50 | 1150 ± 50 | 1500 ± 50 | 1470 ± 50 | 1750 ± 50 | 1730 ± 50 | 1890 ± 50 | 1870 ± 50 | 2250 ± 50 | 2200 ± 50 |

| Breaking load, N | ≥ 77 | ≥ 87 | ≥ 100 | ≥ 110 | ≥ 117 | ≥ 130 | ≥ 135 | ≥ 140 | ≥ 150 | ≥ 165 |

| Specific breaking load, cN/dtex | ≥ 6,7 | ≥ 7,5 | ≥ 6,7 | ≥ 7,5 | ≥ 6,7 | ≥ 7,5 | ≥ 6,7 | ≥ 7,5 | ≥ 6,7 | ≥ 7,5 |

| Elongation at a load of 45N, % | 5,5 ± 1,0 | 5,5 ± 1,0 | 4,0 ± 1,0 | 4,0 ± 1,0 | 3,5 ± 1,0 | 3,5 ± 1,0 | 3,0 ± 1,0 | 3,0 ± 1,0 | 2,5 ± 1,0 | 2,5 ± 1,0 |

| Elongation at break, % | 13 ± 2,0 | 13 ± 2,0 | 13 ± 1 | 13 ± 1 | 13 ± 1 | 13 ± 1 | 13 ± 1 | 13 ± 1 | 13 ± 1 | 13 ± 1 |

| Linear shrinkage of the yarn at 177 ° C x 2 min x 0.05 cN/tex | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 | 3 ± 1 |

| Mass fraction of spinning oil on the yarn | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 | 0,6 ± 0,3 |

| Number of pneumatic connections per 1 m. | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 | 7 ± 2 |